PK2D

2 Component Dispenser

Variable Ratio

Recommended for manual and robotic applications.

Ideal for most 2 component (2 K - 2 part) meter, mix and dispense applications, including hard to handle abrasive, heavy filled, thixotropic and/or odd ratio materials.

Features and Benefits

- Linear Displacement Pump (LDP) - Double acting positive displacement rod pumps (Patented)

- Continuous metered flow (virtually pulse-free) = Shorter Cycle Time

- Two Component Variable Mix Ratio – 1:1 to 100:1 (+/-1%) = Long Term Utility

- Dynamic flow rate control 1cc/min. to >gal/min. = Precision Flow Control

- Viscosity range 1cps to heavy non-flow abrasive compounds = Universal Pump Utility

- Pressure range 1psi to >3,000psi = Universal Pump Utility

- No Pistons, Check Valves, Flow Meters = No Slip Factor, No Calibration, Reliability

- Low shear = Density Integrity of Syntactic Compounds

- Cross-Over Valve (XV4) – Automated 4-way directional flow control valve (Patented)

- Replaces check valves for load/dispense functions during LPD reciprocations = Reliability

- Allows pressure balancing inlet/outlet pressures = Continuous Pulse-Free Metered Flow

- PLC Servo Motor Pump Drives Control

- Enables Precision Mix Ratio, Flow Control and Factory Automated Control Functions

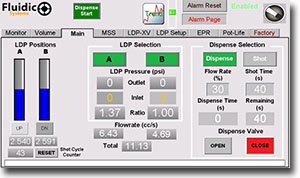

- HMI 10" Color Touch Screen

- No Mechanical Control Adjustments, Statistical Process Reporting (SPR), Control Integrations, Diagnostic Troubleshooting, PM

- Monitoring, Remote Control Access

Standard Features

|

Optional Features

|

Technical Specifications

Mix ratio range A:B ...................................................................1:1 to 100:1*

Mix ratio tolerance range ...................................................................... ±1%*

Minimum shot size.................................................................0.5 g/0.018 oz)*

Minimum flow rate ....................................................5 cc/min (0.17 fl.oz/min)*

Maximum flow rate ...............................................10,000 cc/min (2.7 gal/min)*

Maximum fluid working pressure ................................................... >3,000 psi*

Air supply pressure range.........................5-8.5 kg/cm2(80-120 psi) @ 20 CFM

Operating temperature range ....................................... 4 to 60 C (40 to 140 F)

Electrical requirements: ....................................120 VAC (60 Hz) 1Φ, 20 amps

.......................................................................220 VAC (60 Hz) 1Φ, 10 amps

Wetted materials ................................................303, 316 SS, TFE UHMWPE

Viscosity range of fluids .................................1 cps to Non-flow abrasive comp.

Fluid Handled ............................................................One or two components

.........................................(epoxies, urethanes, silicones, acrylics, polyesters)

*Application dependent